Description

Oil Pipline Cast iron flame arrestor is safety device that stops flame of inflammable gas and liquid from spreading and prevents backfire from causing explosion. It is usually installed on tanks or pipes that transport or discharge flammable and explosive gas, for instance, torches, Heating combustion system, Oil Gas Recovery System and other flammable and explosive gas system.

With the assistance of advanced technology from the UK and Germany, we developed the device with our progressive processing equipment and faultless testing equipment. The Corrugated Plate Flame Arrester we made is particularly applicable to many special medium such as Hydrogen, oxygen, liquefied petroleum gas. And the following is the advantage of our device: compact structure, high reliability, explosion-proof and anticorrosion fire arresting chip-ware, strong water-resistance, easy cleaning etc.

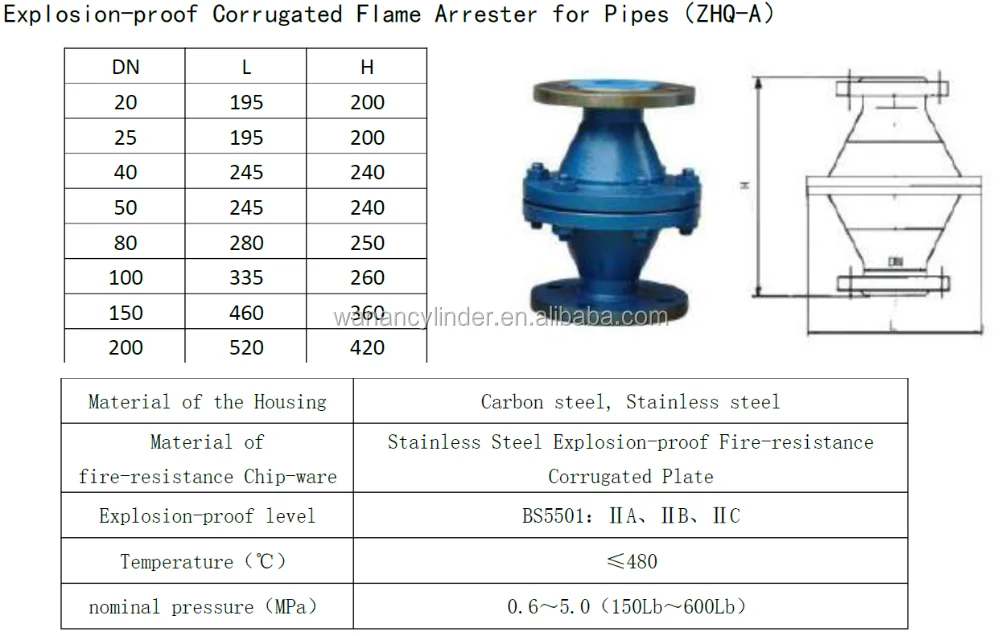

Parameters

1. Applicable to petrochemical products whose flashing point is lower than 60℃, such as Gasoline, kerosene, light diesel oil, toluene etc.

2. Temperature:≤480℃.

3. Material of the Housing: Carbon steel, aluminum alloy, stainless steel; SUS304, SUS304L, SUS316, SUS316L.

4. Material of Fire-resistance Chip-ware: Stainless steel corrugated plate.

5. Explosion-proof level: BS5501: ⅡA, ⅡB,ⅡC.

6. Standard for Manufacture and Testing: SY/T0512-1996.

7. Standard for Flange: HG/T20592-2009.

Please note in order contract if GB, SH, HGJ, JB, ANSI, JIS and other standards are required or there is a need for Pressure change.

Ordering Information

Choosing the proper flame arrestor is critical to the safety of equipment and personnel. Before ordering, please consultant our technical team. And following basic information should be made clear before ordering:

1. Length of pipe between the arrestor and the ignition source without bends

2. Length of pipe between the arrestor and the ignition source with one 90° bend

3. Length of pipe between the arrestor and the ignition source with multiple bends

4. Flame stabilization at stoichiometric mixture and ambient temperature not to exceed 140°F (60°C)

5. Operating Pressure

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000usd, in="" advance.="" payment="">=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us